Rotary engine vs Piston engine: Know the differences.

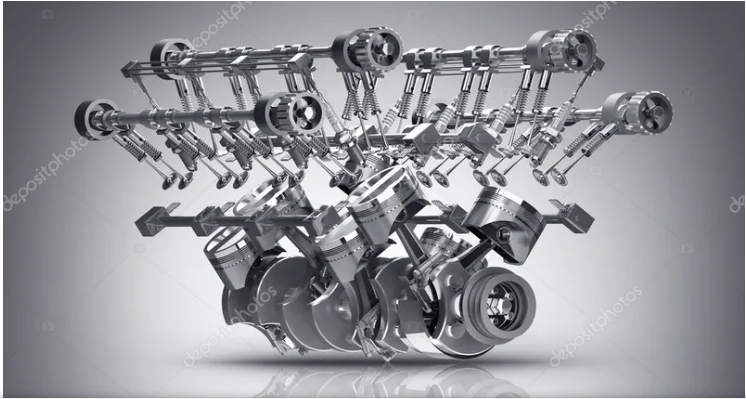

The internal combustion engine has always been the beating heart of a car, the majority of cars you see on the street will have one thing in common, a traditional inline 4-cylinder engine with anywhere between 1.4 and 2 litres or more, performance-oriented or larger vehicles will likely feature engines with more cylinder in a variety of configurations such as the inline five straight sixes V6, V8, V10, V12 , and V16.

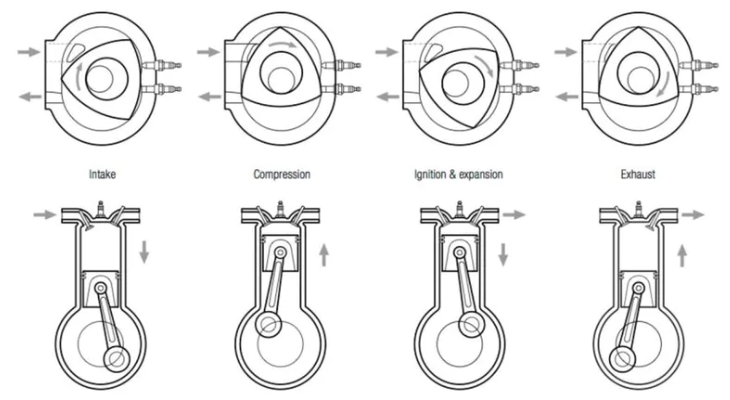

In 1951, Felix Wankel got this idea in his head, that if you put a triangular rotor in a well-designed circled, oval-is shape, you could make an engine.. or a rotary engine, the rotary engine is the black sheep of the engine world whose approach to intake compression power and exhaust are wildly different.

The principle of an engine is to convert one form of energy into mechanical energy. While all of these engines will perform differently they all go about their business in the same way the. Read all about the differences and the pro’s and con’s of a Piston Engine and a Rotary Engine.

SAME BASIS BUT DIFFERENT PROCESS

For a normal four-stroke engine, to produce power an engine needs to do four things, suck air into the engine compress their air with a fuel mixture ignite the air and fuel mixture with a spark and finally expel the burnt air fuel mixture out into the exhaust, the engine under the bonnet or hood of 99.9% of our cars will execute this process using pistons and cylinders.

The piston descends drawing air into the cylinder via open intake valves at the same time fuel is injected into the cylinder as the piston travels back up the cylinder. The air and fuel mixture is compressed which increases its temperature after which a spark ignites the air and fuel mixture to force the piston back down the cylinder.

As the piston rises again in the final exhaust stroke the burnt air and fuel mixture is pushed out of the cylinder via an open exhaust valve and into the exhaust system, diesel engines work in much same way except for one thing instead of a spark igniting the air and fuel mixture a diesel engines compresses and therefore heats the air fuel mixture more greatly meaning that it ignites without the need for a spark.

The only exception here is on start-up where a glow plug is needed, it’s this process of suck, squeeze bang and blow in traditional petrol and diesel engines that make your car move by the crankshaft that carries the piston power from the engine to the wheels.

What about the rotary engines?

In fact, they work on the same four-stage basis but the way in which a rotary goes about this process is very different, however because there are no cylinders or piston instead a big rotor does all the hard work. If we keep things simple by looking at a single rotor engine there are five main components:

1) front plate

2) the rotor housing

3) the rotor itself

4) A rear plate

The fifth component is an eccentric shaft that connects to the rotor acting like the crankshaft in a traditional engine the rotor housing that, the rotor sits in features an intake port two spark plugs and an exhaust port as the rotor spins it creates a vacuum over the intake port which sucks air and fuel into the chamber.

As the rotor continues round covers the intake port after which the air and fuel is then compressed at the equivalent of top dead center in a piston engine two spark plug fire forcing the rotor round further until it reaches the exhaust port to expel the burnt air and fuel mixture and there you have it.

WHAT’RE THE PROS AND CONS OF EACH ENGINES TYPE?

This list is pretty long so make yourselves comfortable !…

Piston engine pros:

– Better materials allow for increased capability to handle higher temperatures and heavier impacts;

– Many have coatings that reduce friction and/or work as a thermal barrier;

– Can greatly increase torque, power, and performance;

Piston Engine cons:

– Require greater skirt to wall clearances depending on the type of material the piston is made of;

– Many get confused with the needed amount of compression. Finding that ideal compression is necessary. This is because if you go too much over it, the pistons get slammed like hammers. Consequently, internal parts can get damaged;

– With so many profiles, it can be confusing to figure out which one is the best for your specific build;

Rotary engine pros:

– Approximately one third of the size of a piston engine of equivalent power output

– Easier to package in small engine spaces than an equivalent piston engine

– high-rpm than a piston engine and that’s why they’re used in motorsports ( Mazda 12A engine was the first engine and only team from outside Western Europe or the United States to finish the entire 24 hours of the 24 Hours of Le Mans race ).

– and This engine sounds pretty cool!!!

Rotary Engine cons:

– rotary engines are well known for burning a lot of oil and that’s because oil is injected directly by a throttle control into the rotor housing to keep the seals lubricated and chambers separated.

– Rotor sealing. This is still a minor problem as the engine housing has vastly different temperatures in each separate chamber section.

Contact us today for inspections on those cylinder heads: BOOK ONLINE

Locate a VAGSPEC branch: